PCB FACTORY

We are professional PCB&PCBA manufacturer,supplying PCB Produc-tion,Components Purchasing, SMT and function testing for companies at home and abroad.

was founded in 2004,we have our own PCB factory and PCBA fac-tory,having passed the ISO9001,ISO13485,TS16949,UL(E332411).

We have sophisticated equipments,advanced technology,excellent technical team,purchase team, QC team and management team.Professional software and hardware engineers who can provide technology support for customers.We ae in charge of the supervision during the pre-production, production,and post-production as well as after-sales technical support &follow-up.

Our main market are Europe,North America,South America and other countries.Main prod-ucts are used for Consumer Electronics,Medical Application,Industrial Control and Toys etc.

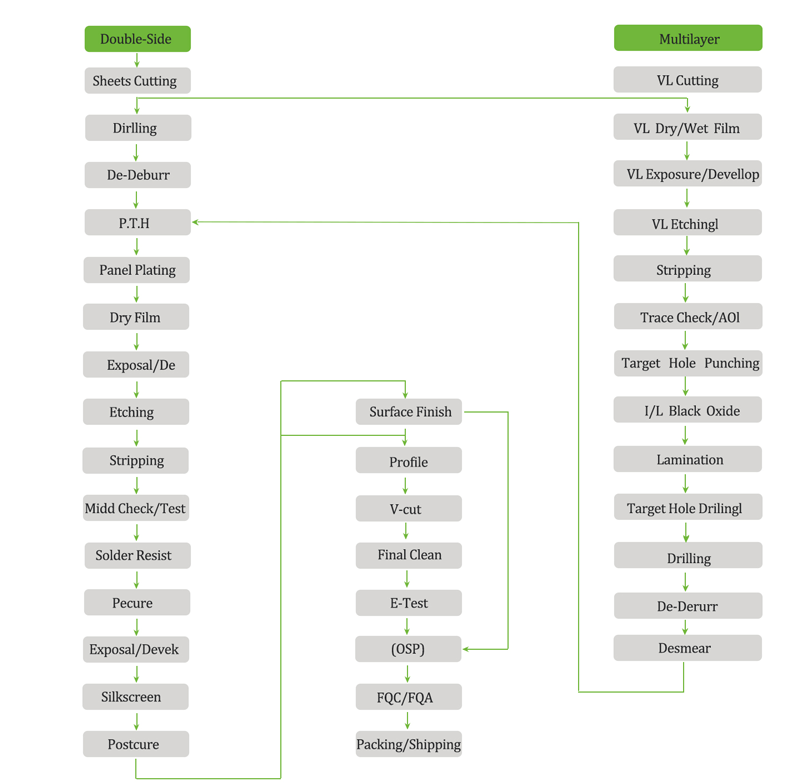

PCB PROCESS FLOW

PCB Production Line

Develop strict quality control standards: Establish a complete quality management system,

Regular quality review and verification: Regular quality review of the production line is carried out to ensure that the product meets the quality requirements and necessary calibration and verification are performed.

Introduce advanced testing equipment: Use advanced testing equipment, such as X-ray inspection machines, AOI (Automatic Optical Inspection), etc., to conduct comprehensive testing of PCBs to ensure product quality.

Training and education: Provide employee training and education so that they understand the company's quality standards and requirements and have corresponding operating skills.

Tracking and monitoring: Track and monitor each batch of PCBs to ensure the stability and traceability of product quality.

PCB Craft Ability Introduction

| The serial mumber | Item | Craft Ability |

| 1 | Surface Finish | Lead free HASL,Immersion Gold,Gold Plating,OSP,Immersion Tin,Immersion |

| silver etc. | ||

| 2 | Layer | 2-30 layers |

| 3 | Min Line width | 3mil |

| 4 | Min Lime space | 3mil |

| 5 | Min space between pad to pad | 3mil |

| 6 | Min hole diameter | 0.10mm |

| 7 | Min bonding pad diameter | 10mil |

| 8 | Max proportion of drilling hole and | 01:12.5 |

| board thickness | ||

| 9 | Max size of finish board | 23inch*35inch |

| 10 | Rang of finish baord's Thickness | 0.21-7.0mm |

| 11 | Min thickness of soldermask | 10um |

| 12 | Soldermask | Green,Yellow.Black,Blue,White,Red,transparent photosensitive soldermask |

| Strippable soldermask | ||

| 13 | Min linewidth of Idents | 4mil |

| 14 | Min Height of Idents | 25mil |

| 15 | Color of silk-screen | White,Yellow,Black |

| 16 | Data file format | GERBER FILE and DRILUNG FILE,PROTEL SERIES,PADS2000 SERIES,Powerpcb |

| ≤FR1ES.CYDB÷ | ||

| 17 | E-Testing | 100%E-Testing;High Valtage Testing |

| 18 | Material for PCB | FR-4,High TG FR4,Halogen free,Rogers,CEM-1 Arlon,Taconic,PTFE,Isola etc |

| 19 | Other test | Impedance Testing,Resistance Testing,Microsection etc |

| 20 | Special technological requirement | Blind &Buried Vias and High Thickness coppe |

PCB electronic testing

FLYING PROBE TESTING

Over the past few years, flying needle testing has become an increasingly popular testing method compared to traditional PCBA online testing due to less stringent design requirements and the elimination of higher fixture and programming costs.

Flying needle testing does not require a dedicated test fixture and can be easily programmed to adapt to different PCBA layouts and designs, making flying needle testing a cost-effective online solution for small and medium batch sizes as well as prototype assembly.

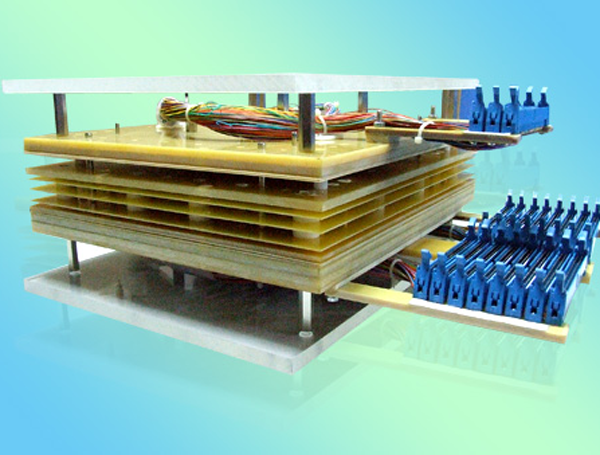

PCB test rack

PCB batch test fixture, also called PCB test rack, is a tool used for batch testing of PCB boards. It usually consists of fixed board clips, circuit connecting wires, test pins, etc. PCB batch testing fixtures are mainly used to improve the production efficiency and testing quality of PCB boards. It can connect multiple PCB boards at the same time and conduct electrical signal testing on the PCB boards through test pins. Using the PCB batch test fixture, first fix the PCB board on the fixed plate clamp of the fixture, and then connect the fixture to the test equipment through the circuit connection wire.

Test equipment usually includes signal generators, logic analyzers, multimeters, etc. During the test process, the test equipment will send electrical signals to the test pins of the PCB board, and the test results will be analyzed and recorded through equipment such as a logic analyzer. Through batch testing of fixtures, electrical problems on PCB boards can be quickly and accurately detected, improving product quality and production efficiency. In short, the PCB batch testing fixture is a very practical tool that can help batch test PCB boards and improve testing efficiency and quality.

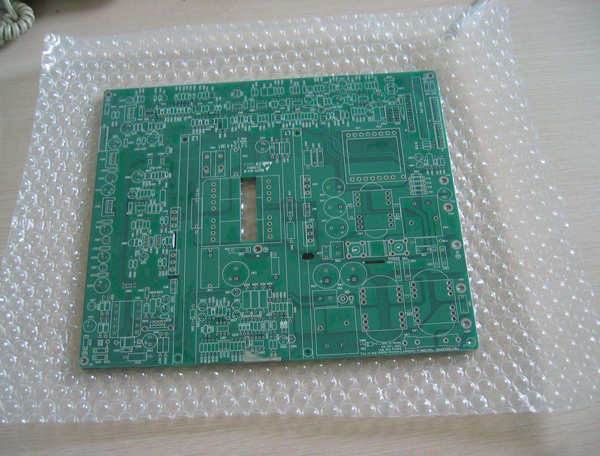

PACKAGE

Here are some considerations for PCB vacuum packaging that we share with you: