We provide professional PCBA welding services to ensure that your electronic products are at the best level in terms of quality and performance.

Why choose our PCBA Welding service?

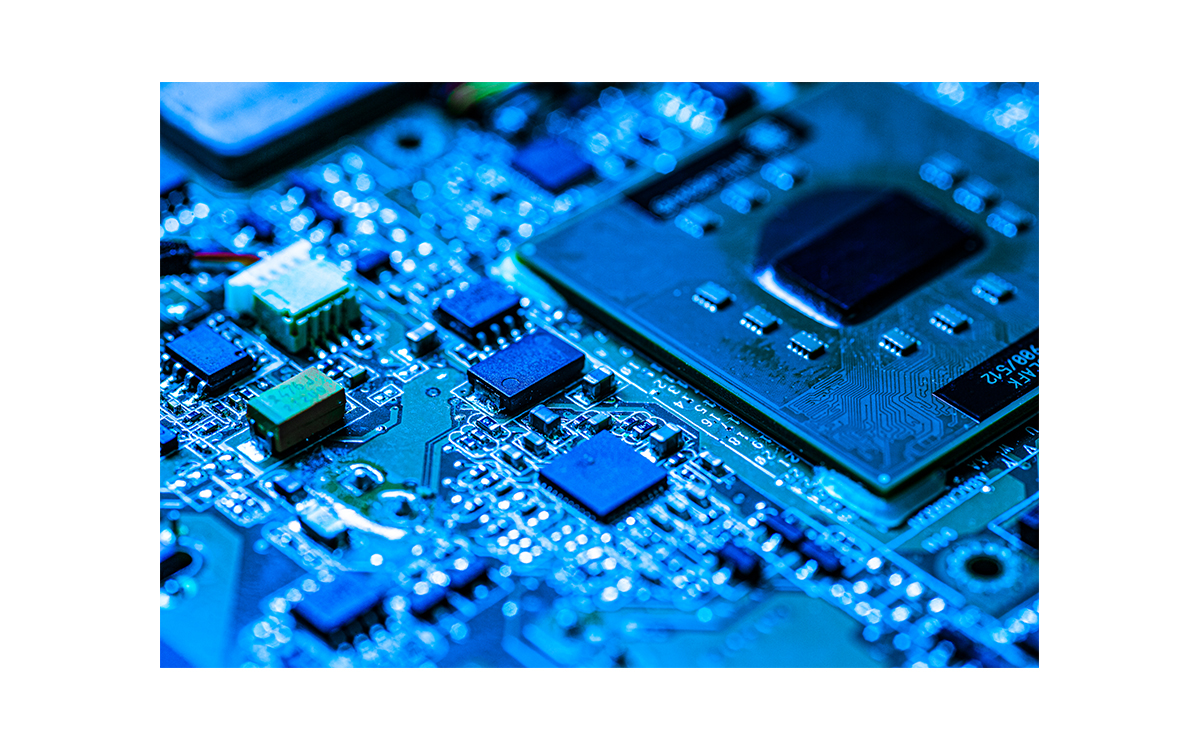

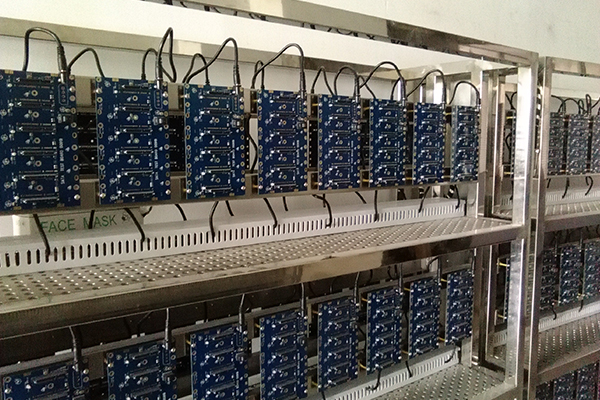

● High quality welding technology: We have an experienced technical team, proficient in various welding methods and techniques, including surface mount technology (SMT) and plug-in technology (THT).

Whether it is a small surface mount component or a large plug-in component, we can complete the welding process accurately and efficiently.

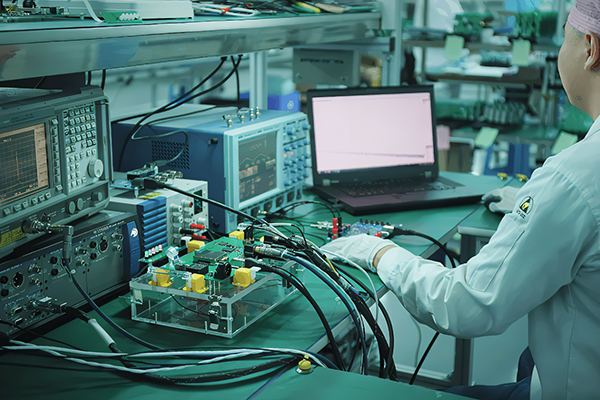

● Strict quality control: We implement a strict quality control process to ensure that every welding process meets quality standards.

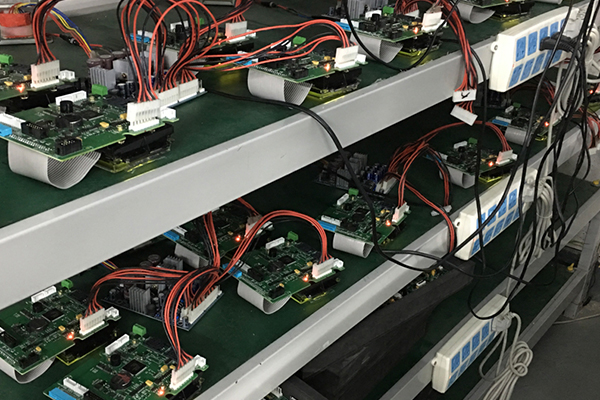

We use advanced testing equipment and methods to conduct comprehensive testing and verification of solder joint connections, welding quality and correct installation of components to ensure product reliability and performance.

● Customized solutions: We can provide customized PCBA welding solutions according to customer needs.

We work closely with our customers to understand their specific requirements and expectations, and provide appropriate advice and technical support to achieve the best welding results.

Before Production

In Production

After Production

Data review

File optimization

BOM Entry Purchase Application

Sample Confirmation(Project Engineer, Customer) Trial-production, Mass production (The project engineer follows up on the entire process)

Project Summary(Record the file for repeat orders) Customer follow-up (after-sales service)

One-Stop Pcba Processing And Manufacturing Service Provider

SMT Line

AOI

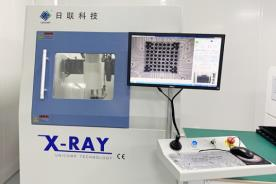

X-RAY

Lead-free reflow soldering

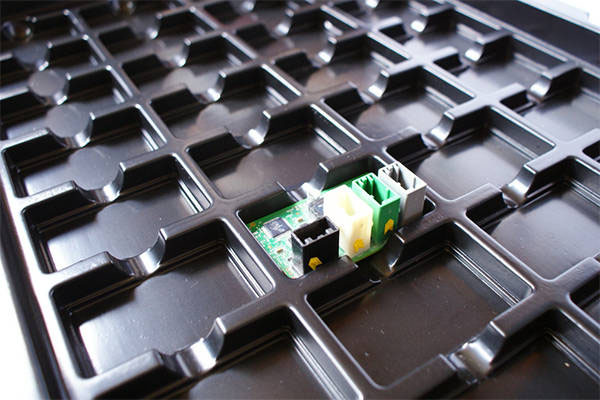

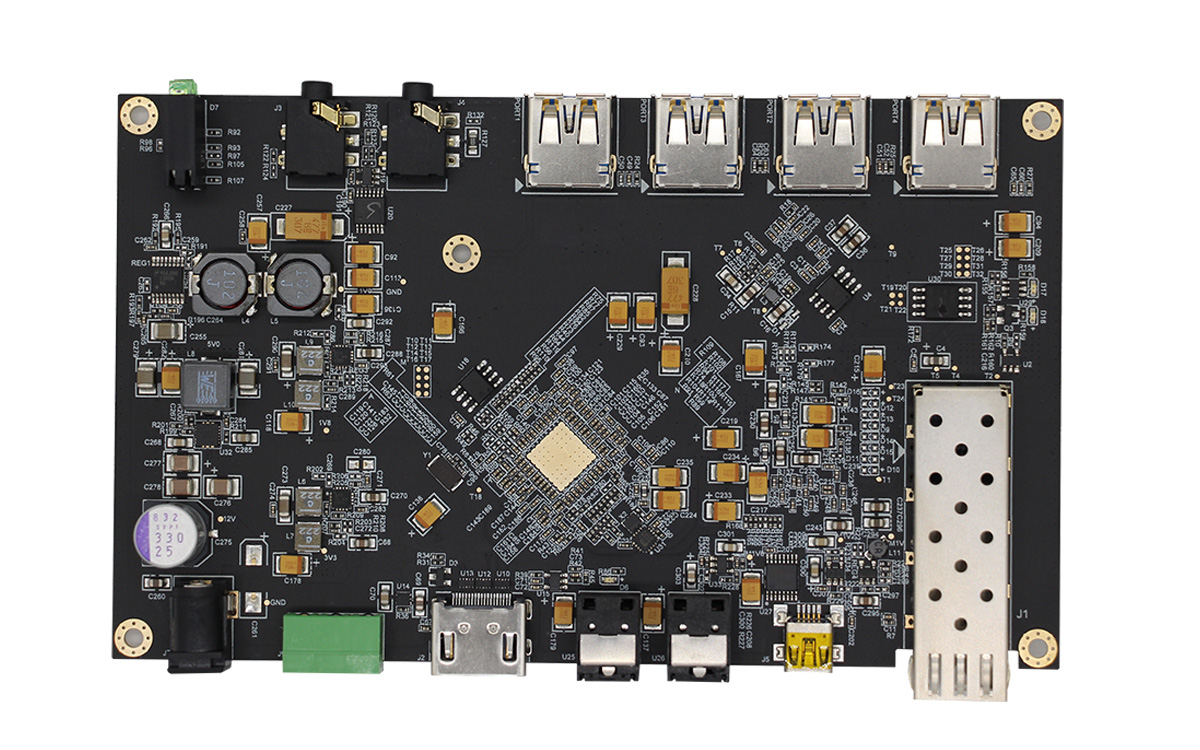

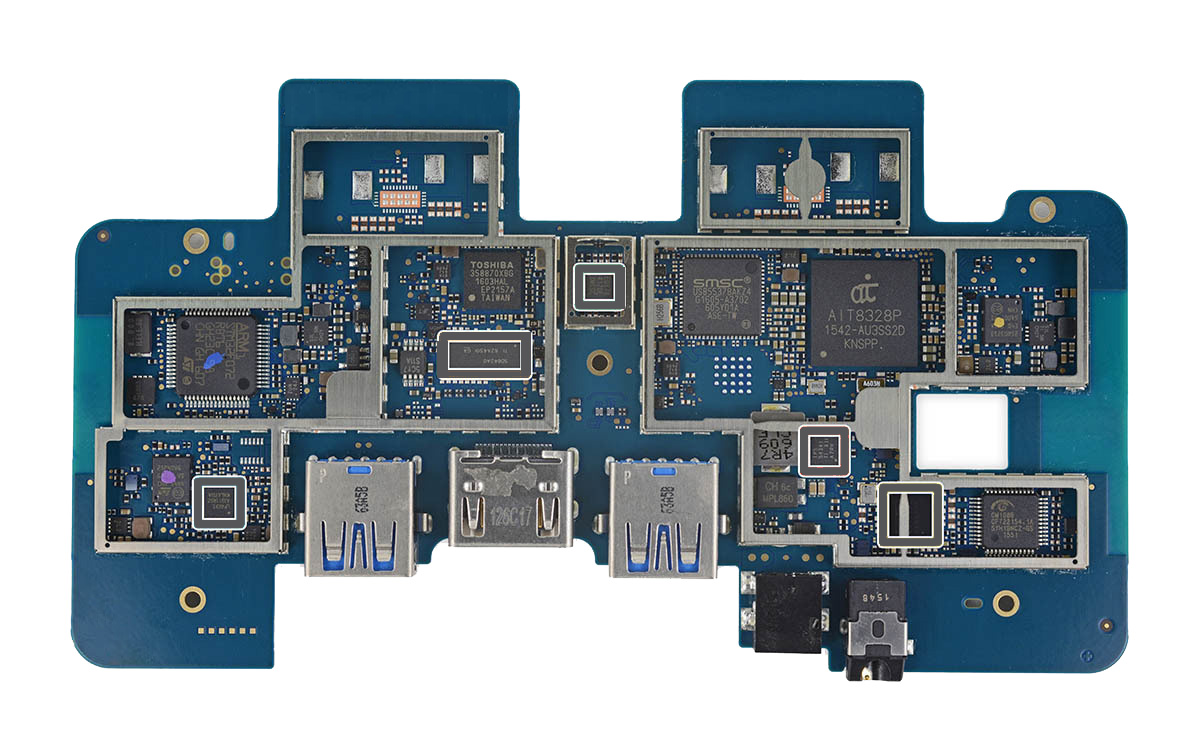

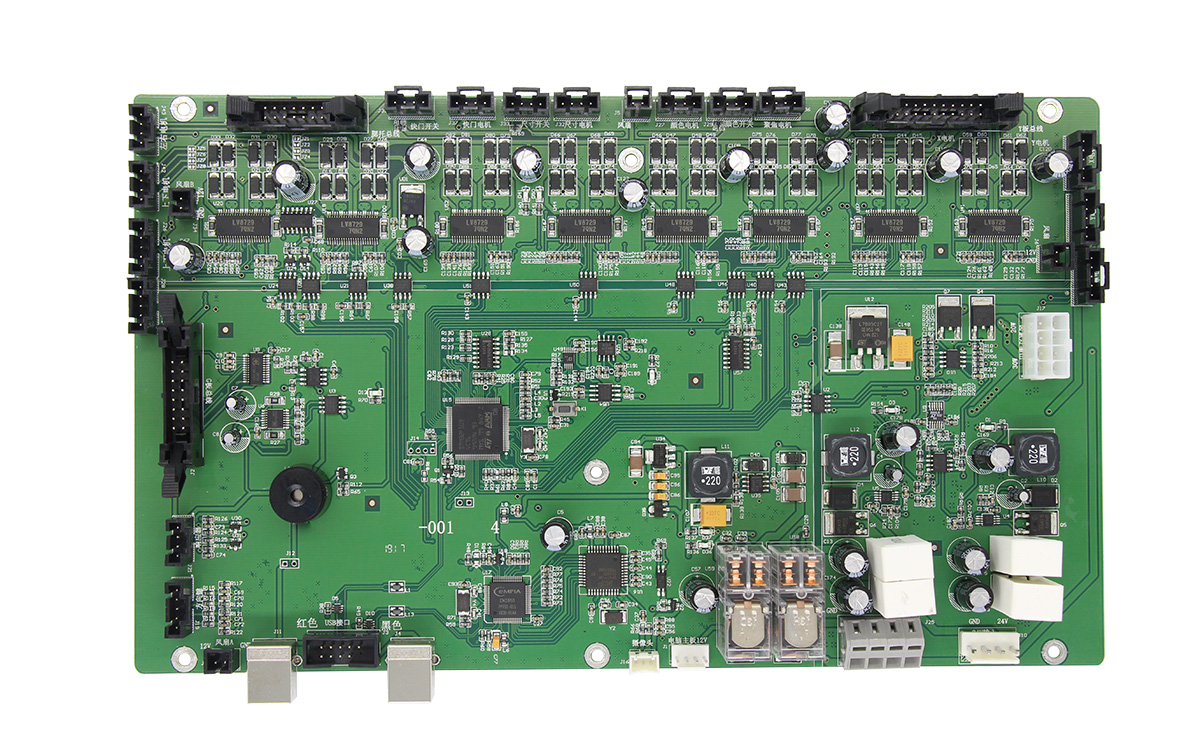

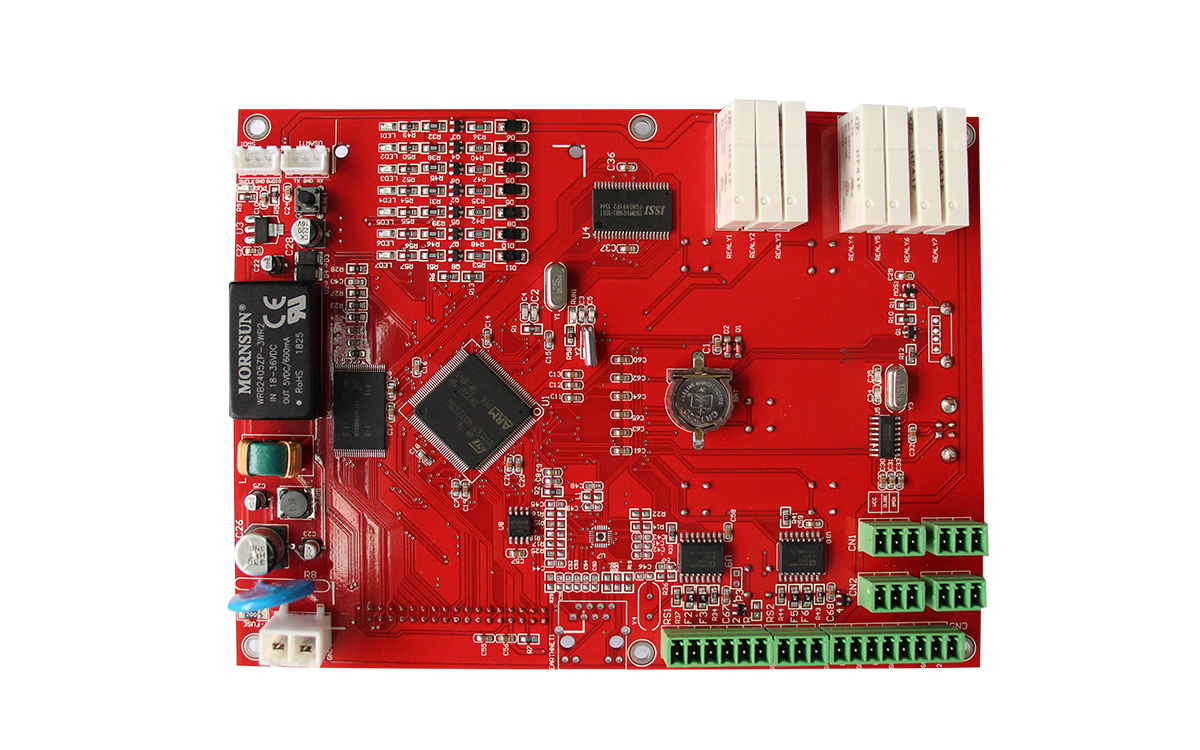

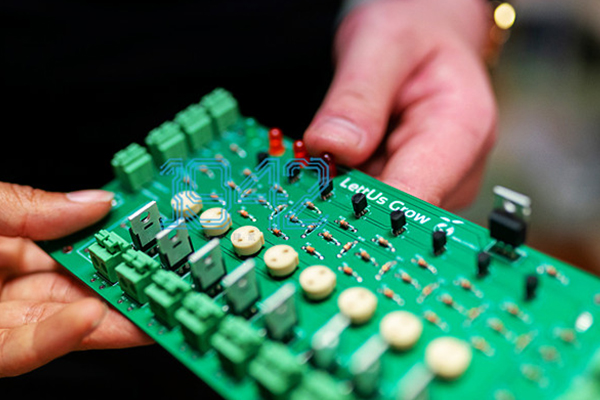

PCBA Partial Case Display

Aerospace Industry

Industrial Control Industry

Consumer Electronics

Consumer Electronics

Medical Industry

Automobile Industry

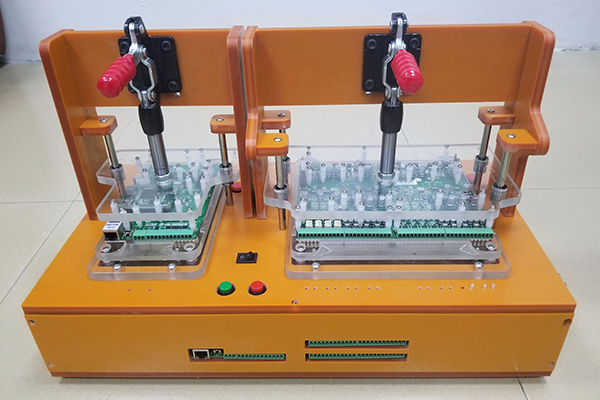

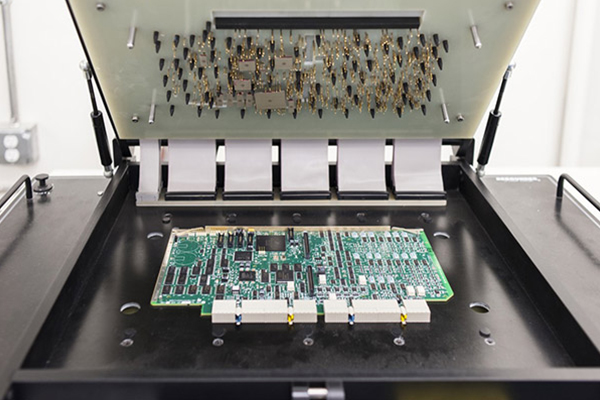

PCB test point is a special point reserved on a printed circuit board (PCB) for electrical measurement, signal transmission and fault diagnosis.

Customers can also design test methods according to test points, and we will make test fixtures for professional functional simulation tests.

☑ Their functions include: electrical measurement The test point can be used to measure the voltage, current, impedance and other electrical parameters of the circuit to ensure the normal operation and performance of the circuit.

☑ Signal transmission: The test point can be used as a signal pin to connect with other electronic devices or test instruments to achieve signal input and output.

☑ Design verification:

Through the test point, verify the accuracy and functionality of the PCB design to ensure that the circuit board works according to the design requirements.

☑ Fault diagnosis:

When a circuit fault occurs, you can locate the fault based on the test point to help engineers find the cause and solution of the fault.

☑ Quick repair:

When circuit elements need to be replaced or repaired, test points can be used to quickly connect and disconnect circuits, simplifying the repair process.